![]() Many are the projects developed by our company. Below is a selection to show their diversity and relevance.

Many are the projects developed by our company. Below is a selection to show their diversity and relevance.

A New proTection devIce for FOD (ANTIFOD)

Participants: UPC, UNIVERSITY OF MANCHESTER, TF, ARA LIMITED, PARTICLE TECHNOLOGY

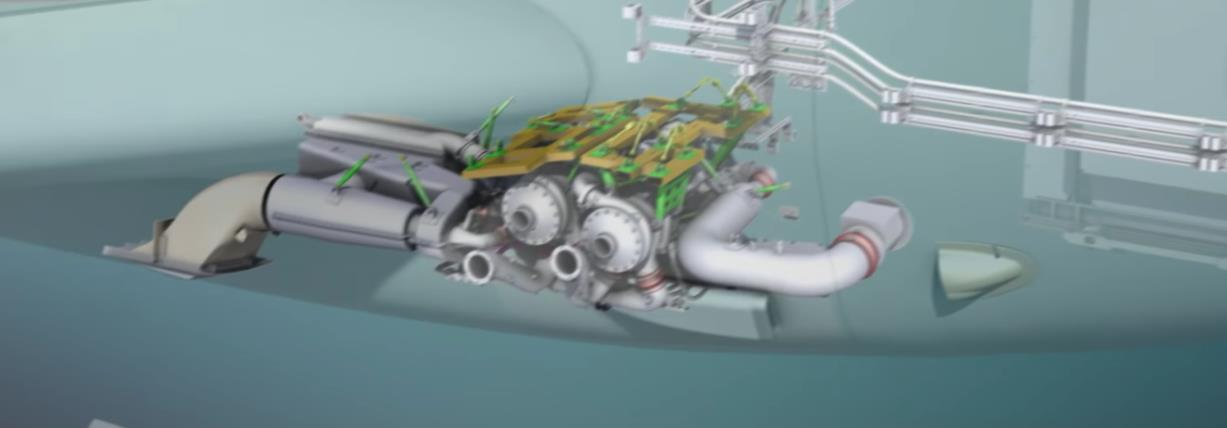

The main objective of this innovation action is to develop a Foreign Object Debris (FOD) protection device applied to an electrical ECS fresh air inlet, validated to TRL5. This will be achieved through the following two-stage design process, each with their own secondary objectives:

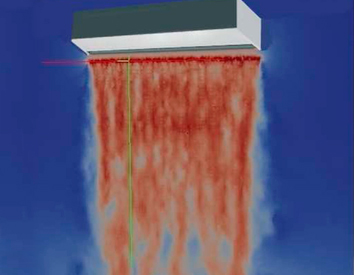

1. Preliminary design, which aims to: a. capture the top level requirements through a survey of the user needs and used to develop a set of baseline candidate concepts. b. use innovative design methods to conduct a concept study. c. verify prototypes rapidly using a combination of CFD and additive manufacturing, as measured by comparing calculated separation efficiency and pressure loss. d. refine the highly ranked concepts via a trade-off study and determine the best suited solution that meets all the top-level requirements, measured through a scoring system. e. produce a preliminary design from the winning concept, including feasibility study, sensitivity analysis, risk assessment, and system requirements report, measured through a preliminary design review (PDR) which demonstrates compliance with the user needs.

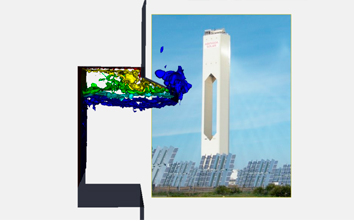

2. Detailed design, which aims to: a. define an aerodynamic geometry for the intake protection and FOD separation device which demonstrably meets the relevant requirements and integrates with the mechanical interfaces of the existing intake scoop inlet, scoop ducting and eECS inlets, and is measured through Wall-Modelled LES simulations. b. produce a detailed design and subsequent manufacture of the full-scale intake protection and FOD separation device. c. design a test bench to validate the intake protection and FOD separation device. d. deliver a final full-scale working prototype to the Topic Leader which demonstrably meets the user needs, as measure.

1. Preliminary design, which aims to: a. capture the top level requirements through a survey of the user needs and used to develop a set of baseline candidate concepts. b. use innovative design methods to conduct a concept study. c. verify prototypes rapidly using a combination of CFD and additive manufacturing, as measured by comparing calculated separation efficiency and pressure loss. d. refine the highly ranked concepts via a trade-off study and determine the best suited solution that meets all the top-level requirements, measured through a scoring system. e. produce a preliminary design from the winning concept, including feasibility study, sensitivity analysis, risk assessment, and system requirements report, measured through a preliminary design review (PDR) which demonstrates compliance with the user needs.

2. Detailed design, which aims to: a. define an aerodynamic geometry for the intake protection and FOD separation device which demonstrably meets the relevant requirements and integrates with the mechanical interfaces of the existing intake scoop inlet, scoop ducting and eECS inlets, and is measured through Wall-Modelled LES simulations. b. produce a detailed design and subsequent manufacture of the full-scale intake protection and FOD separation device. c. design a test bench to validate the intake protection and FOD separation device. d. deliver a final full-scale working prototype to the Topic Leader which demonstrably meets the user needs, as measure.